The ⅛” single flute end mill shipped with your machine, has been set up and programed into the tool table as tool 10. (Part Number 528508 - Carbide, Plastic Cutting End Mill - Square Upcut Single Flute). Do not use for plunging or cutting metals.

Distance from B-Table to Center of A axis rotation “B-table offset”: 0.88XXin. This value changes for each machine and is included on a paper with each machine. If you have misplaced yours, please email us at info@pocketnc.com and we can find it for you!

TOOL OFFSET SETUP PROCEDURE

...

Home machine

Clear any offsets using The “Zero Coordinate system” button located under the Machine dropdown menu. The Z values seen in the DRO readout should read 0.00000.

Move A table to 90 degrees using the command “g90 g0 A90” within the MDI command window.

Clean off any debris on the B-table.

Jog Z in the negative direction until the base of the tool is close enough to the B axis table that the 1-2-3 block will not fit between the two.

In increments of 0.01” or less, jog the Z axis positive until the 1-2-3 block slides between the tool and the table

Repeat this step with smaller increments until the tool position is measured past 3 decimal places

Use the current Z position on the Machine interface to calculate the tool offset using the equation below:

...

Example -(3.000)+(0.8861)+(-0.9131)=(Tool Offset) = (-3.027)

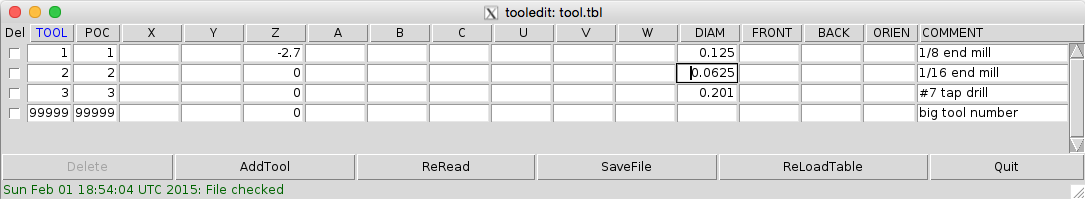

Input the calculated Tool Offset within the Tool Offset table found under => File => Edit Tool Table ...

TOOL HOLDER CHANGE

Turn off spindle and loosen the (3) spindle screws using the 3mm wrench.

Tap spindle holder with the back end of the 3mm wrench and take out the tool holder.

Reverse process for installing a new tool holder, being sure to tighten the (3) spindle screws evenly.

TOOL CHANGE

Use the Pocket NC spindle wrench and the 3mm driver (Both found in the tool kit).

Turn off spindle and place the 3mm driver into one of the 3 spindle screws.

Using the Pocket NC spindle wrench loosen the collet nut while holding the spindle in place using the 3mm wrench.

Change out or move tool and then reverse the process to tighten the tool holder.

Remember to adjust the tool offset after changing or adjusting a tool.

SET TOOL LENGTH METHOD 1(PREFERRED METHOD)

This is done in AXIS by clicking File>Edit tool table as shown in the image below. If the window pops up for you, go on to step 4. If it doesn't, go to step 2 for a Mac or step 3 for a PC

The Mac my be having issues with the SSH connection. Two situations likely have occurred at this point.

2a. You have had your Machine interface open for more than about 10 minutes and you need to restart the machine by powering it down and then restarting it to get this edit tool table option to work this way. You can also try option 2b directly below or go to the second method found below after the Windows explanation.

...

2b. You may have opened the tool table properly and due to where it is on the Linux screen you need to open it by going down to the Dock and right click on the Xming Icon and select “Show All Windows” This will likely bring up the tool table and you can select it from there. If this does not work go to the second method found below after the Windows explanation.

...

3. With a PC you are likely having an issue where the Tool Table is off the screen and you need to bring the window up onto the screen. This can be done by hovering over the Xming icon until the two window comes up. Then right click on the tool table window and select “Maximize”.

...

4. To set the tool table to reflect our earlier example, we will change the value of Z to -3.027 and the tool diameter to 0.125". It is important to remember that this value is the diameter of the tool, not the diameter of the shank. After updating the values for your tools, press "Save File" and then "ReRead". Once you are done with your updates, quit to the main AXIS window. Once in the main AXIS window, click File>Reload Tool Table to update the offsets.

After you have reloaded the tool table, you can check that the offset took by typing G43 H1 and pressing enter (that is if you changed tool 1, type H2 if you changed tool 2). Once you have entered G43 H#, you will see TLO Z changes to the number you input in the tool offset page. Most tools will fall between -2" and -3".

...

If you are consistently using the same tooling throughout your programs, you can bypass having to change the tool offsets by making sure you use the same tool numbers when generating toolpaths in you CAM software.

SET TOOL LENGTH METHOD 2 (IF METHOD 1 DID NOT WORK)

If you have a Mac Open up a secondary Terminal window by right clicking on terminal and selecting “New Window”. If you have a PC right click on “Putty” and select your desired boot option to open a second window.

...

2. In the second terminal window, sign into your Pocket NC. Then type in the command “scite” (Command sensitive) to open the text editor.

3. Once Scite opens, go to File>Open.

4. Select “pocketnc” (red arrow) → “linuxcnc” → “configs” → “ARM.BeagleBone.PocketNC” → Change to “All File” (Blue arrow) → “tool.tbl”

...

5. With “tool.tbl” open, edit the tool table as needed. In this format you must use the notation defined below.

Example - T10 P10 Z-3.21 D0.123; Tool Ten

Description - Tool# _ Program# _ Zoffset _ Diameter of tool _ ; Tool notes

When in doubt follow the notation of the other tools.

...

6. If the asterix (*) is by the file name (see blue arrow above) the file is not saved. To save the File go to “File” → “Save”.

7. Once the Tool table file has been edited go back to the Machine interface window. Two windows can be open at the same time if you follow step 1 of this method.

8. In the machine interface window go to “file” → “reload tool table…”.

Important - Without doing this step you will not be able to use the new tool offset values in machine kit, unless you restart the machine.

| View file | ||

|---|---|---|

|

...